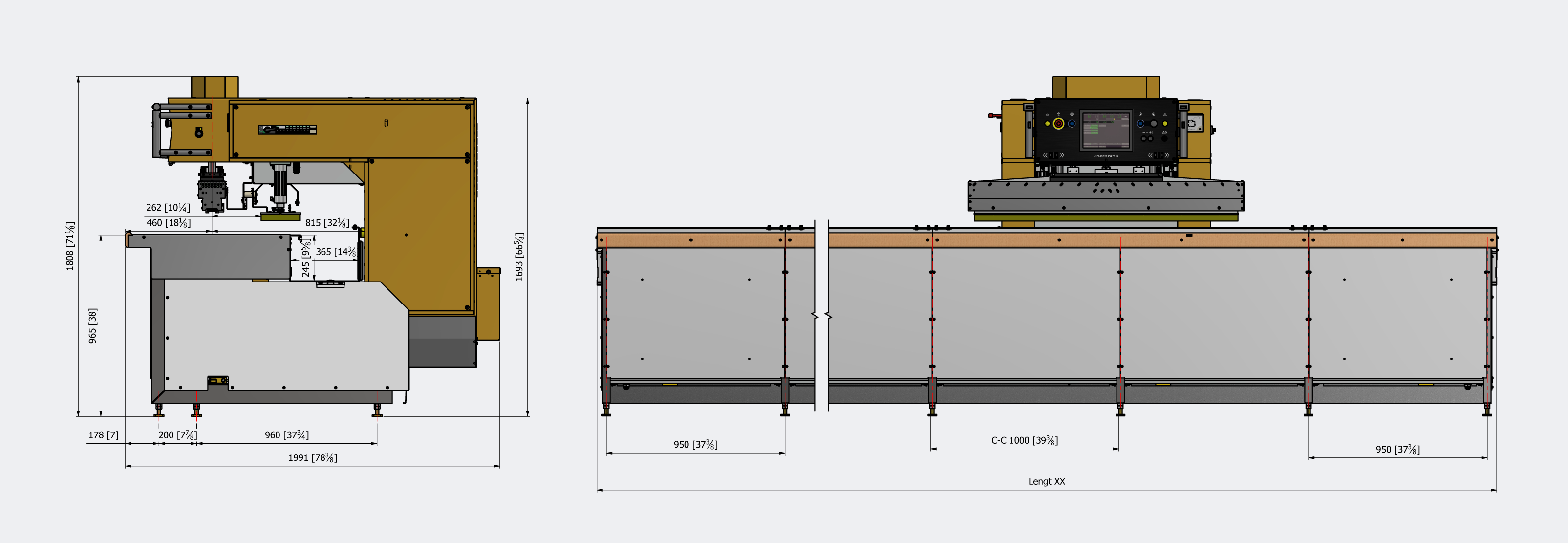

Forsstrom

TDW-Mega

Large Travelling HF Welding Machine

16-25 kW emitted HF.

650-1000 cm² weldable surface.

825 mm free space behind the electrode

400 mm max electrode width

70 mm daylight (with a 45 mm high electrode)